In the world of health and wellness, few tools are as universally loved and essential as the yoga mat. But have you ever wondered what goes into making the mat that supports your sun salutations and savasana? Step into the world of a yoga mat factory, where innovation, sustainability, and quality craftsmanship meet to produce the foundation for mindful movement.

From Concept to Creation

The journey of a yoga mat begins with design. Engineers and product designers collaborate to create products that not only meet functional needs—grip, durability, comfort—but also align with evolving consumer values, such as sustainability and ethical production. This design phase includes material selection, thickness adjustment, color decisions, and textured surface testing.

Common materials include natural rubber, TPE (Thermoplastic Elastomer), and eco-friendly PVC alternatives. Each material has different properties—rubber is known for grip and earth-friendliness, while TPE offers durability and lightness. In leading factories, responsible sourcing and eco-certifications ensure raw materials are kind to both the body and the planet.

Precision Manufacturing

Once the materials are sourced, production begins. Large rollers press and mold the material under heat and pressure, then cut it into precise dimensions. At this stage, surface textures such as ridges or grip lines are etched into the mat to improve traction and aesthetics.

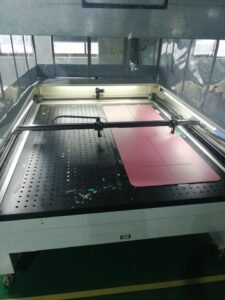

Injection molding machines, cutting presses, and laser printers may be used to create sharp edges, vibrant logos, or even intricate designs. Automation and quality control software ensure every mat is uniform, strong, and safe for long-term use.

Quality Control Matters

Yoga mats undergo rigorous testing before leaving the facility. Quality assurance teams inspect mats for consistency in thickness, resilience under pressure, and non-slip performance. They might even conduct grip tests under sweaty conditions and odor resistance checks to ensure a pleasant user experience.

Each mat is also examined for chemicals or allergens, especially in factories that serve health-conscious or vegan marketplaces. Certifications such as OEKO-TEX or SGS are frequently sought to validate non-toxicity.

Sustainability in Practice

Modern yoga mat factories are increasingly focused on reducing their environmental footprint. Waste scraps are repurposed, energy-efficient equipment is used, and water recycling systems help cut down resource consumption. Sustainable packaging—like recyclable wrapping or compostable boxes—is an added step in keeping the final product aligned with green living principles.

Where Wellness Begins

What makes a yoga mat factory special isn’t just the machines or materials—it’s the people and principles behind them. Every mat that rolls off the line represents a commitment to health, mindfulness, and sustainability. In a sense, the yoga factory isn’t just making fitness equipment—it’s crafting individual spaces for peace, growth, and self-connection.

So next time you step onto your mat, know that it’s more than foam or rubber—it’s the result of thoughtful design, conscious production, and a deep respect for the practice of yoga.